Depth Filtration System

Product Introduction

Alioth Depth Filtration System is a flexibly configured and easy-to-use system that is compatible with mainstream depth filters or depth filter holders available on the market. It can also be paired with Alioth own brand of depth filter holders, and is suitable for primary and secondary depth filtration sessions. Customers can flexibly choose different sizes of depth filtration systems based on different liquid volumes and process requirements, thus meeting the needs of small-scale, pilot-scale and commercial-scale production. The depth filtration system includes depth filter holders, system power pumps, pressure transmitters, flow meters, turbidity meters, and other control and monitoring systems required for GMP production. It has excellent adaptability from clinical production to large-scale commercial production.

Product Properties

- Compatible with different types of consumables and depth filter holders of various areas

- Compatible with mainstream brands of filter holders in the market

- Manual and fully automatic control levels

- Diaphragm valves and pressure transmitters, which meet cGMP's requirements for designing sanitary dead angle in the structure

- conforming to pharmaceutical-grade standards

- Possibly equipped with hydraulic device and filter holder; effort-saving, safe and easy operation

- Available in a full range of specifications for laboratory research scale, clinical pilot production scale, and commercial large-scale production

- Resistant to acids, alkalis, organic solvents, etc., and meeting SIP/CIP as well as cleaning validation requirements

- Adopt industry-standard chuck interface connection

- Provide special customized services based on actual process requirements and plant conditions of customers

- Holders are made from 316 L stainless steel

- Surface finish Ra < 1.2 μm, liquid-contacting surface finish Ra < 0.6 μm

- Compact and rational system design, resulting in a small footprint

- Flexible system configuration, and optional inlet turbidity, outlet conductivity, and other functions as needed

Product Characteristics

| Device type | 1000 L/H | 2500 L/H | 5000 L/H | 8000 L/H | 15000 L/H |

| Structural material | Holder: 316 L Valve: 316 L / EPDM / PTFE Pump: 316 L / EPDM / TPE TC gasket: EPDM / PTFE Pipeline: 316 L Frame: 304 Sealing materials and plastics in contact with liquid meet the biological reactivity testing standards of USP 88 for Class VI materials, and comply with CFR 177.2600 and CFR 177.1550 |

||||

| Performance parameters | Compatible with mainstream filter holders in the market. The maximum working pressure may vary depending on the characteristics of different filter holders For Merck POD filters, the maximum working pressure can reach 50 psi @ 25°C | ||||

| Maximum differential pressure |

Forward: 3.5 bar (50 psid) @ 25°C; 1.0 bar (15 psid) @ 80°C Reverse: 2.1 bar (30 psid) @ 25°C |

||||

| Rated pressure | Up to 2.1 bar, 30 psi | ||||

| Utility requirements | 1x220V P+N+PE 50Hz Power: 2 KW |

3x380V 3P+N+PE 50Hz Power: 3 KW |

3x380 V 3P+N+PE 50Hz Power: 5 KW |

3x380 V 3P+N+PE50Hz Power: 8 KW |

3x380 V 3P+N+PE 50Hz Power: 10 KW |

| Electrical enclosure | IP 54 | ||||

| Compliant | 3C / CE (2004 / 108 / CE), UL 508 A | ||||

| Ambient temperature | 4 - 25℃ | ||||

| Ambient humidity | 10% to 90%, non-condensing | ||||

| Process fluid temperature | 4 - 30℃ | ||||

| Inlet/Outlet | ASME BPE 3 / 4'' TC | ASME BPE 1'' TC | ASME BPE 1.5'' TC | ASME BPE 2'' TC | ASME BPE 2'' TC |

| Holder connection | 1 Inlet 1 Outlet | 1 Inlet 1 Outlet | 2 Inlet 2 Outlet | 3 Inlet 3 Outlet | 3 Inlet 3 Outlet |

| Pipe size | ASME BPE 3/4'' | ASME BPE 1'' | ASME BPE 1.5'' | ASME BPE 2'' | ASME BPE 2'' |

| Pumping speed | 100 ~ 1000 LMH | 250 ~ 2500 LMH | 500 ~ 5000 LMH | 800 ~ 8000 LMH | 1000 ~ 15000 LMH |

| Recommended filter area (m2) | 1.1 ~ 2.2 | 1.1 ~ 5.5 | 1.1 ~ 11 | 1.1 ~ 22 | 5.5 ~ 33 |

| Automation level | Fully automatic, optional manual control, pump with intelligent diaphragm, pressure displayed on diaphragm pressure gauge |

||||

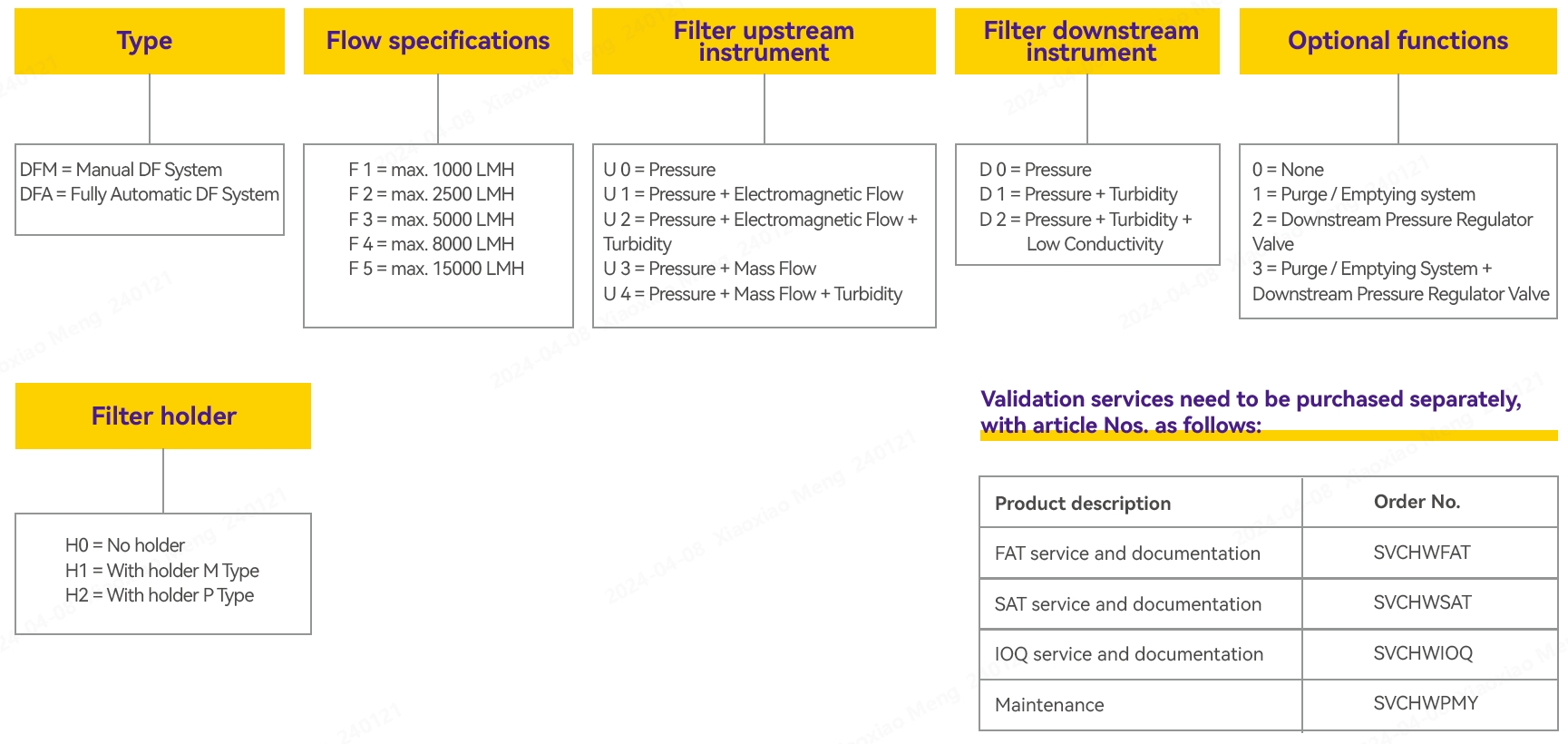

Ordering Information

For further information, please contact us and Alioth technical team will provide a comprehensive service for your filtration process.