Semi-automated Tangential Flow Filtration System

Product Introduction

Alioth Semi-automated Tangential Flow Filtration System adopts modular design. It may be designed as desktop- or ground-based version, and can be equipped with a rotor pump or a diaphragm pump. With holders of different areas, it can automatically control tangential flow rate or inlet pressure, TMP and ΔP, thus purifying the liquid of antibodies, vaccines, blood products and gene therapy drugs through concentrating, exchanging fluid, desalting, dealcoholizing and other purification operations. This system enables a certain level of automation and also meets the requirements for data integrity. It is an ideal choice for laboratory process development, pilot-scale clinical drug production, and large-scale commercial production.

Product Properties

- Available in multiple specifications: Adaptable to common filtration membrane areas ranging from 0.02 to 200 m2

- Equipped with PLC, weighing unit, manual valves, circulation pump, flow meter, pressure gauge, etc.

- Feedback control of TMP and ΔP to improve working efficiency

- Compatible with ultrafiltration filters and hollow fibers

- Optional process tanks with different designs

- Optional replenishing pump to achieve equivalent volume of fluid exchanging

- Equipped with an emergency stop button

- With grading alarm and three-tier authorization management

- Compliant with FDA 21 CFR Part 11 requirements for electronic records and electronic signatures

- Compliant with audit trail

- Pre-reserved interface for integrity testing of filter

- Pre-reserved SCADA system data interface

- Optional online pH/conductivity/UV instruments

- Optional CIP and water flux detection functions

Typical Applications

- Vaccine purification

- Monoclonal antibody purification

- Blood product purification

- Purification of novel therapeutic drugs

PID Flowchart

Product Characteristics

| Product specification | 0.02-0.3m2 | 0.1-0.5m2 | 0.5-2.5m2 | 2.5-5m2 | 5-10m2 | 10-20m2 | 20m2+++ |

| Product code | TFS0M3 | TFS0M5 | TFS2M5 | TFS5M0 | TFS 10M | TFS 20M | CUSTOM |

| Automatic control level | Automatically control tangential flow rate or inlet pressure TMP, manually control valves, and automatically record data | ||||||

| Operating pressure | Maximum 5 bar | ||||||

| System pressure resistance | Maximum 6 bar | ||||||

| Pipeline fittings | SS 316L Ra ≤ 0.6 μm ( 0.4 μm optional ) | ||||||

| Sanitary connection | Tri Holder | ||||||

| Manual valve | EPDM, SS 316 L | ||||||

| Pressure measurement | 0-6 bar, ± 0.1 | ||||||

| Flow detection | Reflux end / permeating end Electromagnetic flowmeter ( mass flowmeter optional ) | ||||||

| Electrical components | SIEMENS / Beijer/Eaton | ||||||

| Operation mode | HMI semi-automatic operation, automatic recording | ||||||

| Minimum circulation volume and residual volume | 0.02-0.3 m2, minimum circulation volume < 200 mL and residual volume < 10 mL for desktop-based version 0.1-0.5 m2, minimum circulation volume < 200 mL and residual volume < 10 mL for desktop-based version 0.5-2.5 m2, minimum circulation volume < 400 mL and residual volume < 10 mL for desktop-based version 2.5-5 m2, minimum circulation volume < 2 L and residual volume < 10 mL 5-10 m2, minimum circulation volume < 5 L and residual volume < 10 mL For customized equipment, theoretical values are calculated based on actual 3D design |

||||||

| Supported languages | Bilingual (Chinese and English), support Chinese input method | ||||||

| Materials of liquid-contact parts |

316 L, Polymer (USP class VI or FDA), EPDM, Santoprene elastomer, medical, Grade epoxy, silicone | ||||||

※Fully automatic systems have various requirements, flexible configurations, and are relatively complex. It is recommended to contact local sales and technical personnel for consultation as soon as possible

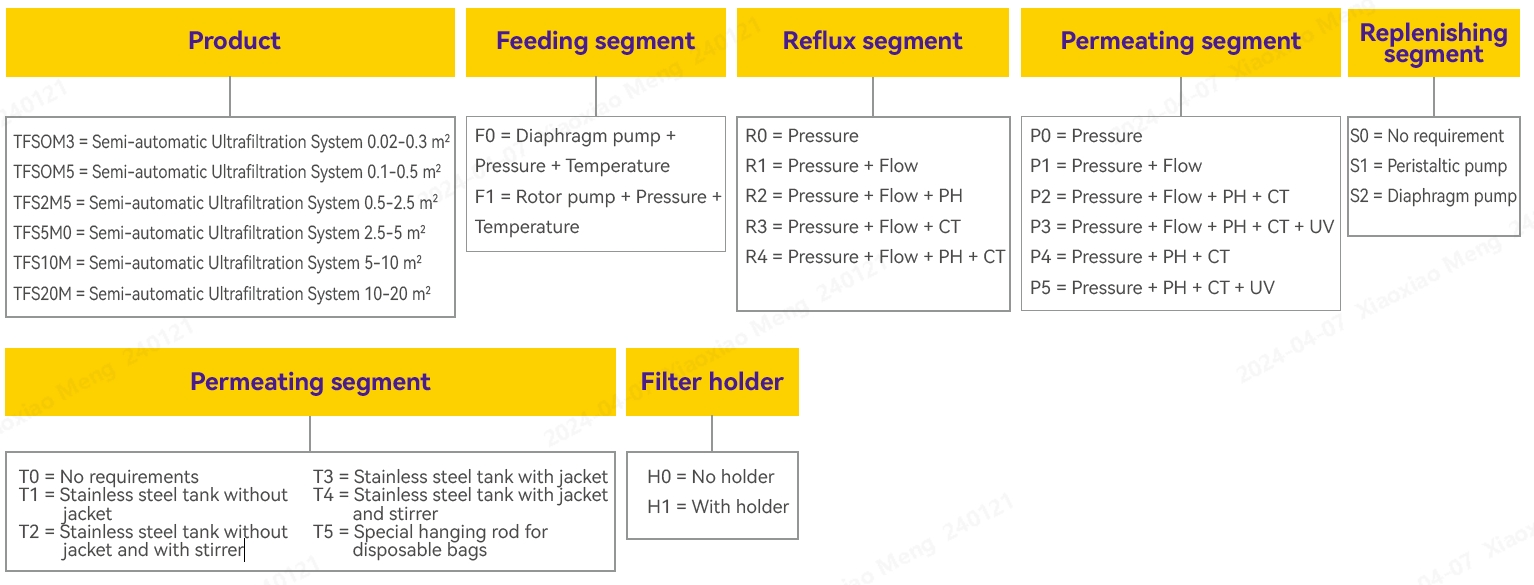

Ordering Information

For further information, please contact us and Alioth technical team will provide a comprehensive service for your filtration process.