Depth Stacked Filter

Product Introduction

Alioth Alidep® Depth Stacked Filters are primarily used for theclarification step in pharmaceutical processes, with stainless steelfilter housing to achieve filtration. There are a variety of sizes to meet the customer's use.

Depth stacked filters have a variety of filter media combinations. Filter media are mainly composed of cellulose, filter aid and positive-charged resins or pure cellulose, and thus have high throughput. Filters can be used in cell culture clarification and provide gradual retentions of cells to reduce turbidity and effectively absorb impurities such as DNA, HCP, endotoxin etc.,reducing the challenges to subsequent purification steps.

Key Features and Benefits

- Multiple size specifications and customized according to customer needs.

- Flexible media selection to optimize customer product development.

- Adapted to current mainstream filter housing and systems.

- Strict production control and release testing, reliable performance, and low process risk.

Typical Applications

- Clarification of CHO cell culture fluid

- Clarification in vaccine production process

- Clarification of yeast fermentation broth

- Clarification of other material liquids

Product Specifications

| Product series | 16 inch 8 cells | 16 inch 10 cells | 16 inch other |

| Effective filtration area (EFA) | 1.8m2 | 2.3m2 | Optional |

| Overall dimension (mm) | 184 mm | 275 mm | - |

| Filter Media | Filter Media Cellulose, Filter Aid, Resin or Cellulose | ||

| Frame and Supporter | Glass Fiber Reinforced Polypropylene | ||

| Stainless Steel Band | 316L | ||

| O-ring | Silicone | ||

| Particle Challenge | Particle Intercept>90% | ||

| Max Operation Pressure | 3.0 bar @ RT | ||

| Max Pressure Differential | Forward:2.0bar@RT Reverse:not recommended |

||

| Endurance to Sterilization | SIP: 123℃ 30min, 3cycles | ||

| Indirect Food Additive | The raw materials of all Alidep® Depth Stacked Filter components comply with the requirements forfood additives in FDA 21 CFR 177-182. | ||

| Toxicity | The raw materials of all Alidep® Depth Stacked Filter components meet the requirements for in vivo biological safety of Class VI plastics in USP <88>. | ||

| Bacterial endotoxin | Endotoxin level of rinsing liquid is < 0.25 EU/mL, which complies with the requirements for water for injection in Chinese Pharmacopoeia and United States Pharmacopoeia. | ||

Product Specifications

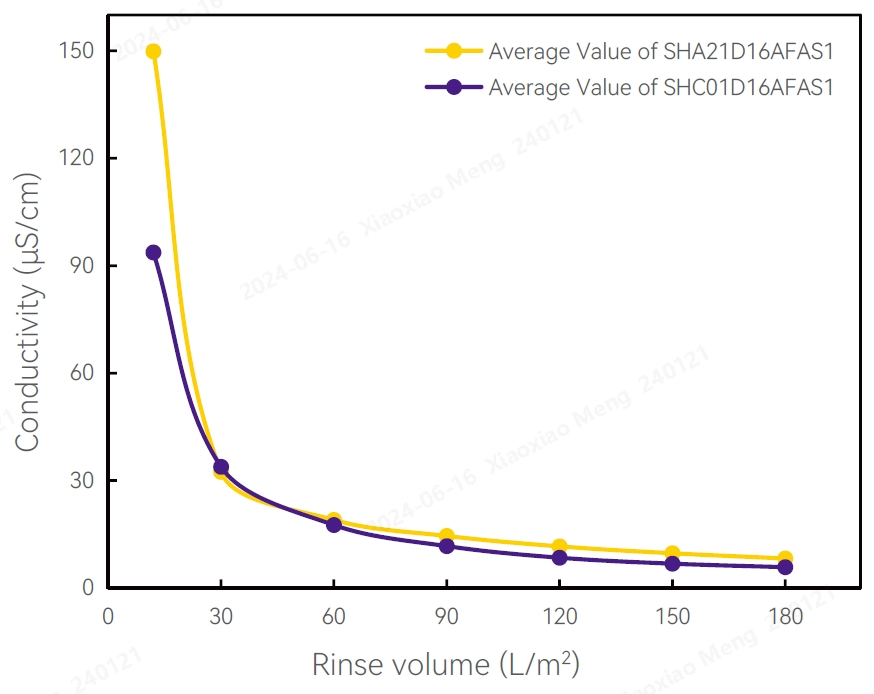

Conductivity Test Results

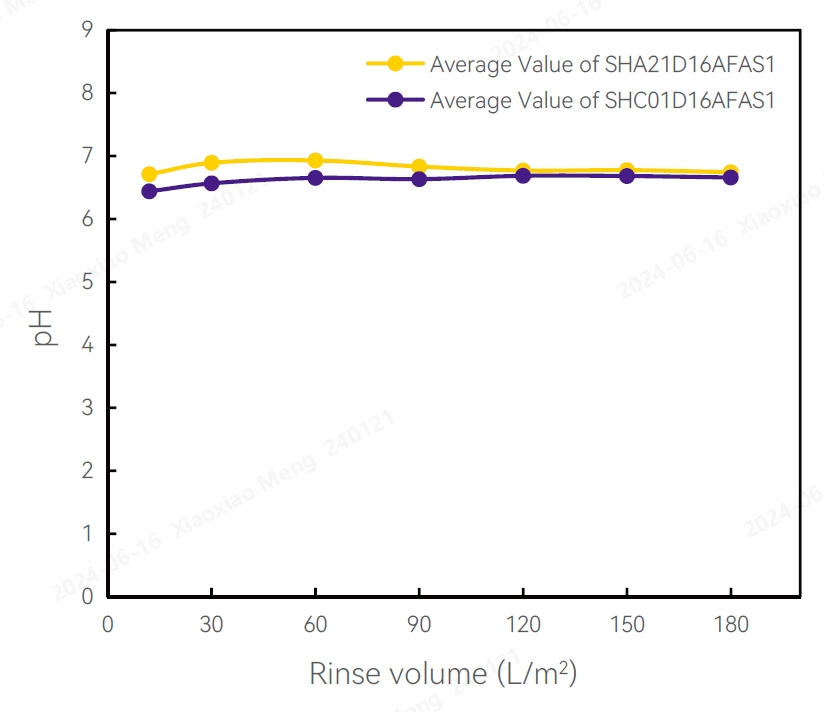

pH Test Results

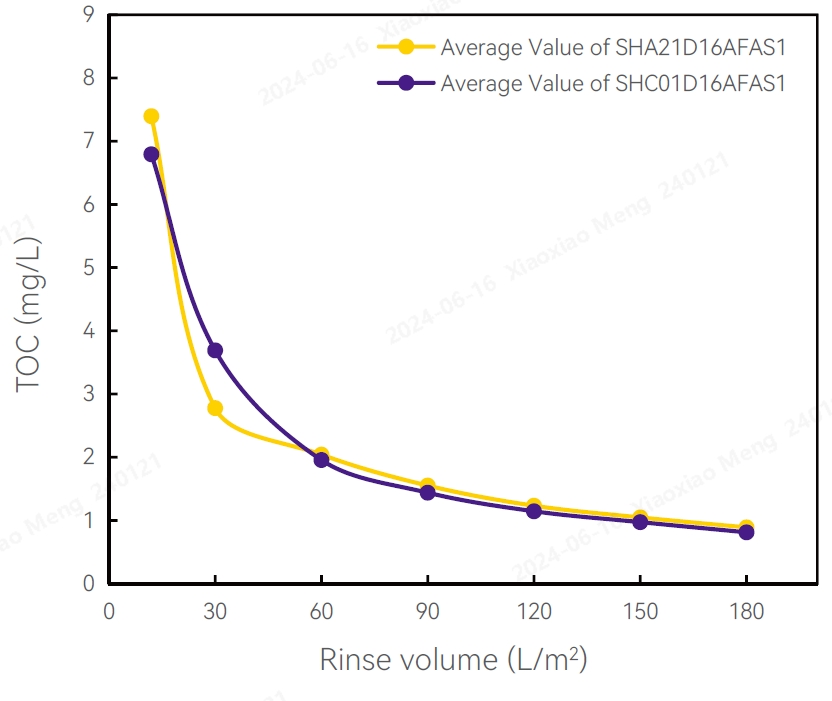

TOC Test Results

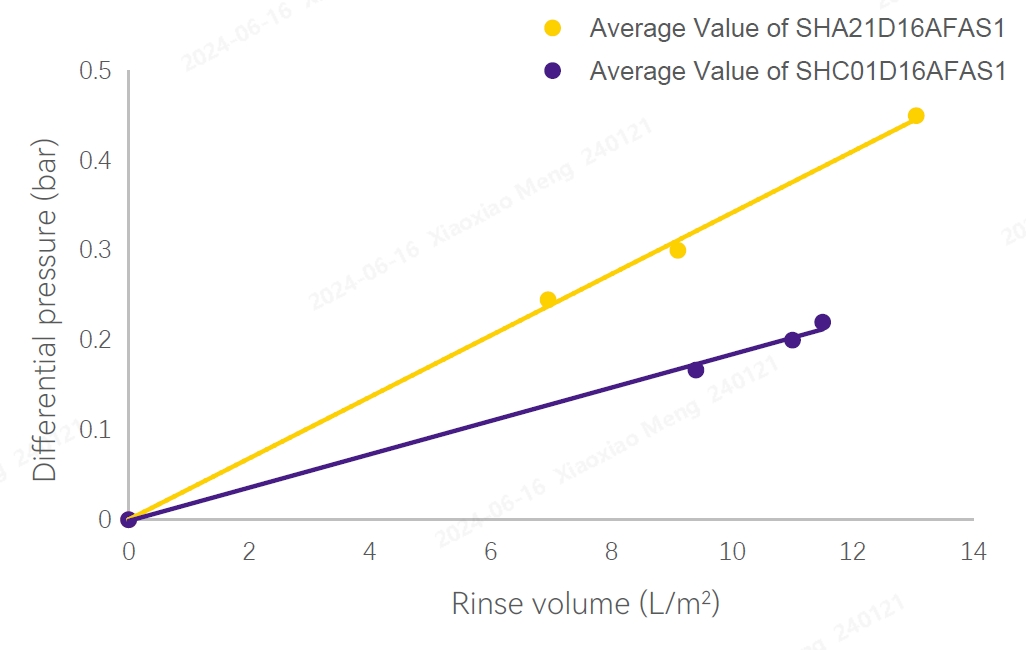

Test Results of Flow Differential Pressure

Validation Methods and Results

| Conductivity | Several filters were randomly selected from different production batches, then rinsed with 100L/m2 pure water for 10-20minutes. The conductivity ranged from 5-8μS/cm. |

| TOC | Several filters were randomly selected from different production batches, then rinsed with 100L/m2 pure water for 10-20minutes. The TOC was about 1mg/L. |

| pH | Several filters were randomly selected from different production batches, then rinsed with 100L/m2 pure water for 10-20minutes. The pH ranged from 6.6-6.8. |

| Endotoxin | Several filters were randomly selected from different production batches, then rinsed with 100L/m2 pure water for 10-20minutes, followed by soaking in pure water for 24 hours. The endotoxin level was < 0.25 EU/mL as indicated by Tachypleus Amebocyte Lysate test. |

| Endurance to Sterilization | Several filters were randomly selected from different production batches, after 3 cycles of SIP at 123℃ for 30min, filters passed air tightness, diffusion flow, hydraulic stress. Flow rate and pressure dropafter SIP met the product quality standard. |

| Hydraulic Stress | Several filters were randomly selected from different production batches, respectively conduct hydraulic stress test at ambient temperature and after 3 cycles of SIP at 123℃ for 30min. High-viscosity solutions was filtered to increase the pressure drop across the filters.Apply forward pulse pressure to the filter at ambient temperature, rinseand conduct diffusion flow. Depth stacked filter can withstand 2.0bar forward pressure at ambient temperature. |

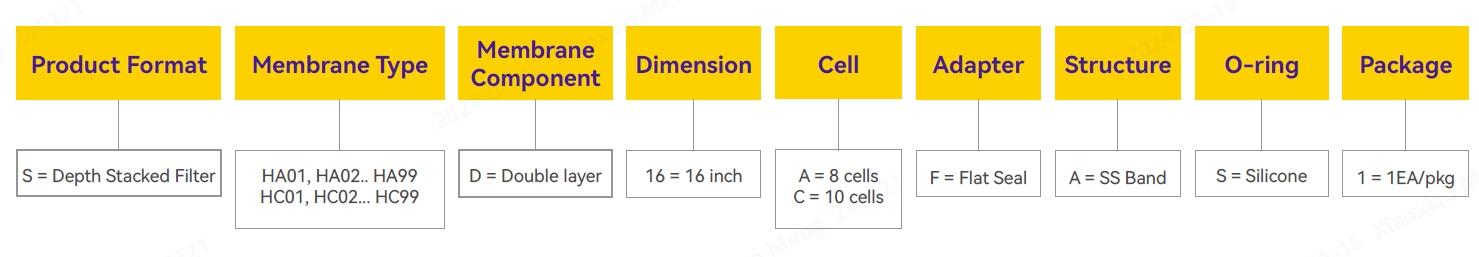

Ordering Information

For further information, please contact us and Alioth technical team will provide a comprehensive service for your filtration process.