Depth Filters

Alioth Alidep® Depth Filter is mainly used for the clarification step in pharmaceutical process, and its disposable design provides greater flexibility for large-scale production.

Alidep® Depth Filter has various media combinations, and is mainly composed of cellulose, filter aids, and positively charged resins. It provides strong dirt-holding capacity and may be used for the clarification of cell culture fluid.

-

-

-

Product Characteristics

Product Specifications

Product Series

Alidep® process development

scale (L series)

Alidep® laboratory scale

(P series)

Alidep® production scale

(M series)

Effective Filtration Area

23 cm2

270 cm2、540 cm2

0.11 m2、0.55 m2、1.1 m2

Overall Dimension

9.4x7.1x4.3 cm

22x14x(7.4~9.6) cm

62x32x(3.1~12.4) cm

Materials of

Construction

Inlet, Outlet and Exhaust Port

Luer connector:

Polypropylene

6 mm hose connector:

Glass fiber-filled polypropylene

Flat end connector:

Glass fiber-filled polypropylene

Frame and Cover Material

Glass fiber-filled polypropylene

Filter Plate

Cellulose, filter aids and resin

Supporting Layer

Polypropylene

O-ring

Silicone

Working characteristics

Aerosol Challenge Test

Aerosol leakage < 0.01%

Maximum Operating Pressure

3.5 bar @ 40°C

Maximum Forward Differential

Pressure

3.0 bar @ 25℃

Maximum Reverse Differential

Pressure

2.0 bar @ 25℃

Sterilization

Resistance

Autoclave: 125℃ 60 min,2cycles

Indirect Food Additive

All component materials meet the requirements of Indirect Food Additive cited in FDA 21 CFR 177-182

Toxicity

The raw materials of all Alidep® Depth Filter components, including filter plates ( mainly made from cellulose, filter aids and resin ), frames and covers made from glass fiber-filled polypropylene, depth supporting nets made from polypropylene, and silicone O-rings, meet the biological safety requirements refering to USP <88> Class VI plastic

Bacterial Endotoxin

The endotoxin level of rinsing liquid is <0.25 EU/mL, which complies with the requirements for water for injection in Chinese Pharmacopoeia and United States Pharmacopoeia

※The thickness of filter is related to the number of filter plate layers

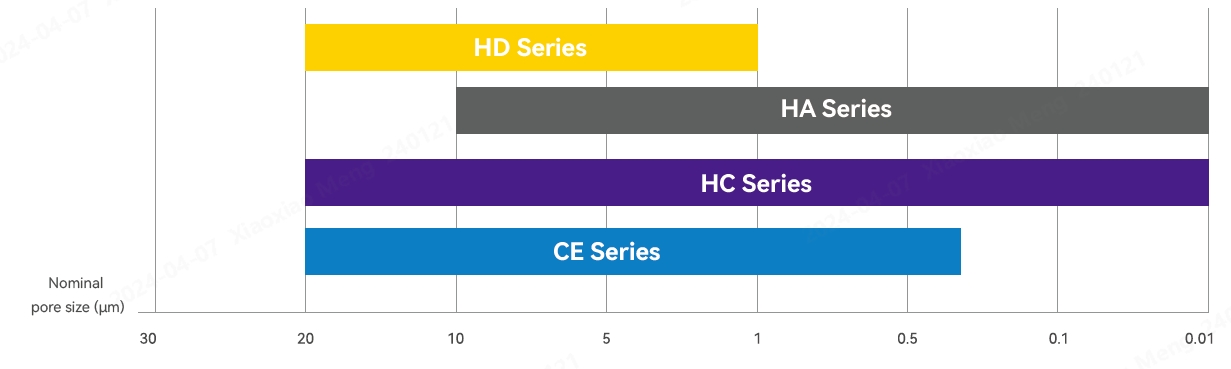

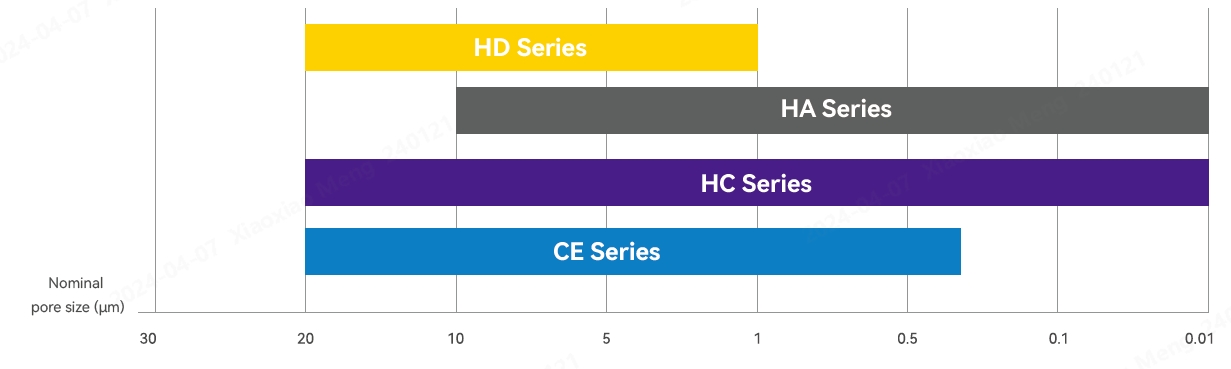

Pore Size Range

Name of medium

Application

Features

Composition

Double-layer HD Series

Primary clarification of cell culture fluid

Two-stage filter plate and open pore, which can retain large particles and fragments

Cellulose, filter aids and resin

Double-layer HA Series

Secondary clarification of cell culture fluid

Double-stage filter plate and dense structure, which can achieve more strict turbidity control

Cellulose, filter aids and resin

Double-layer HC Series

Direct clarification of cell culture fluid

Double-stage filter plate, which is designed to clarify material liquid with a low cell density

Cellulose, filter aids and resin

Double-layer CE Series

Clarification of plasmids and virus particles, etc.

Double-stage filter plate, which features low adsorption

Cellulose

Pore Size Range

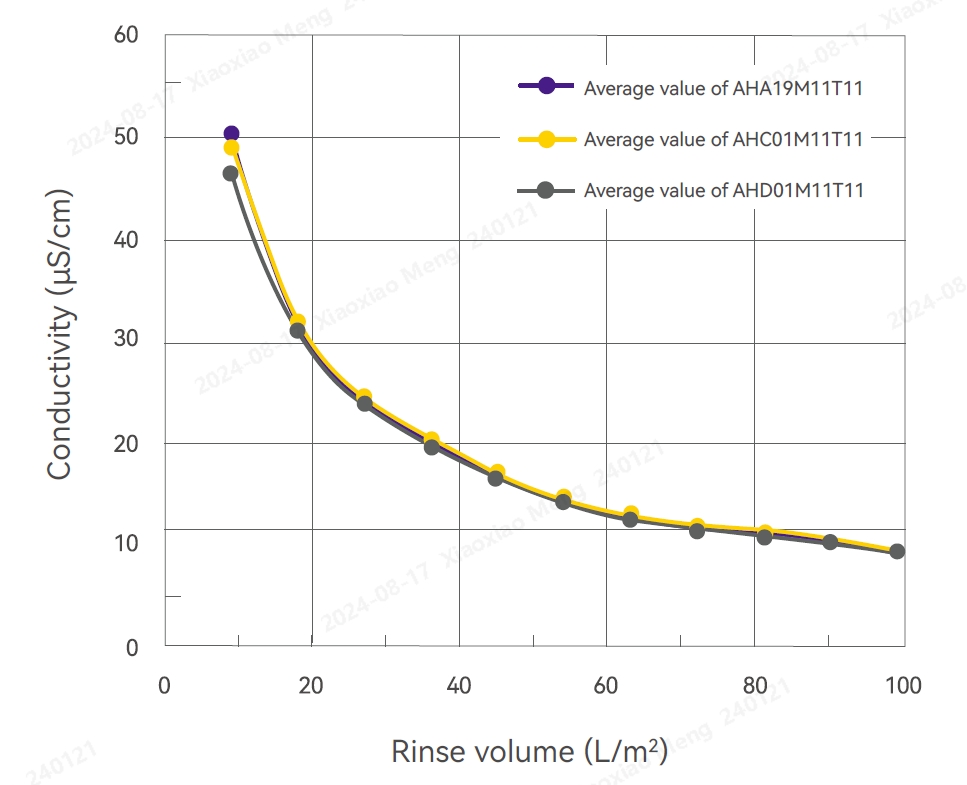

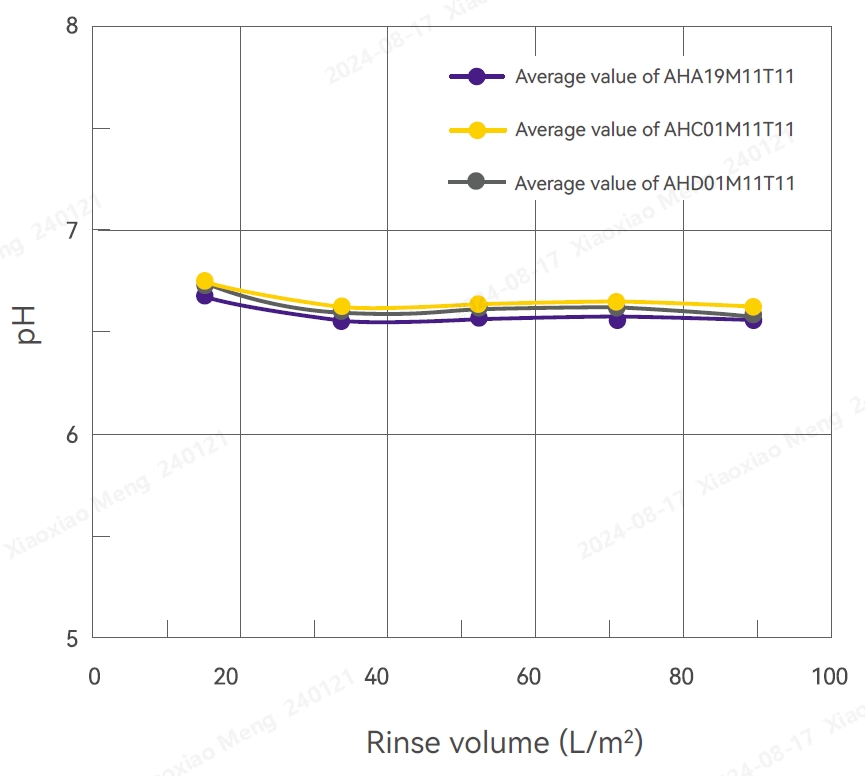

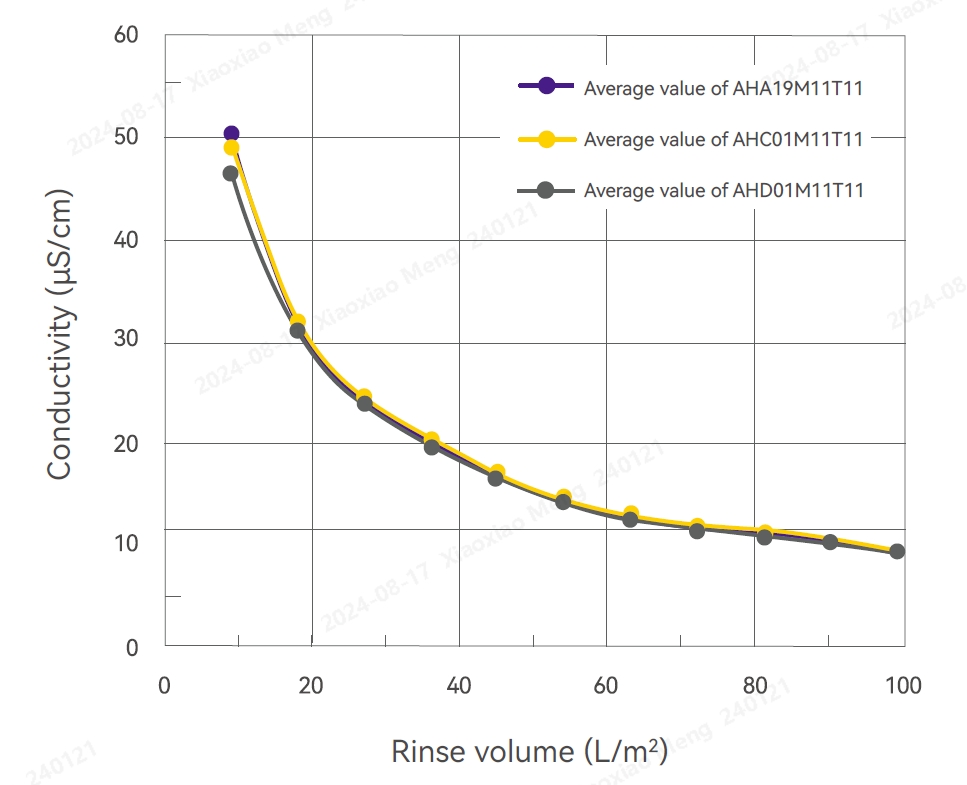

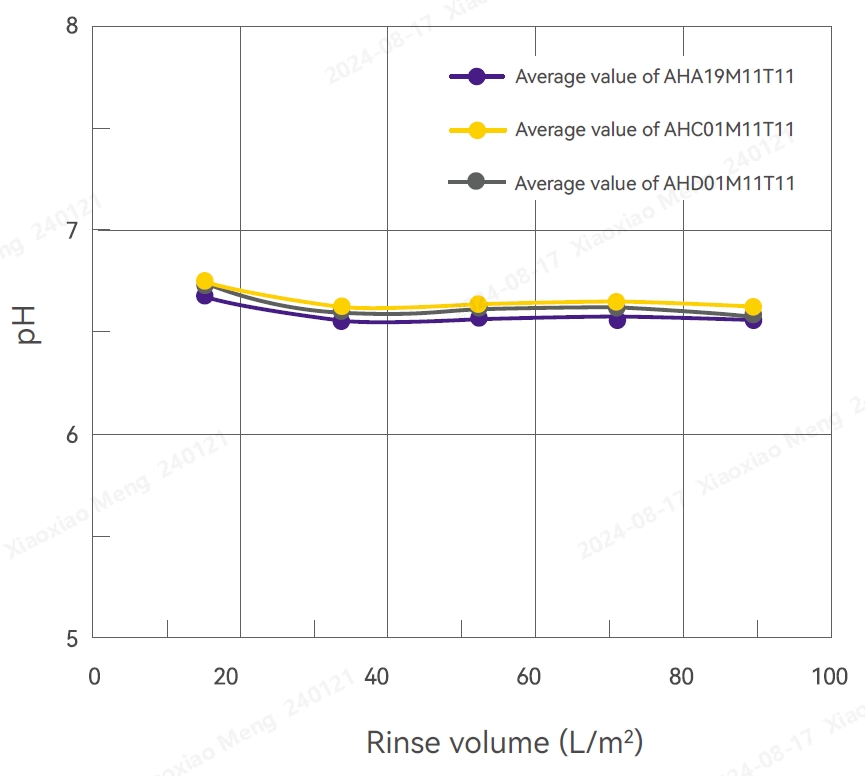

Conductivity Test Results pH Test Results

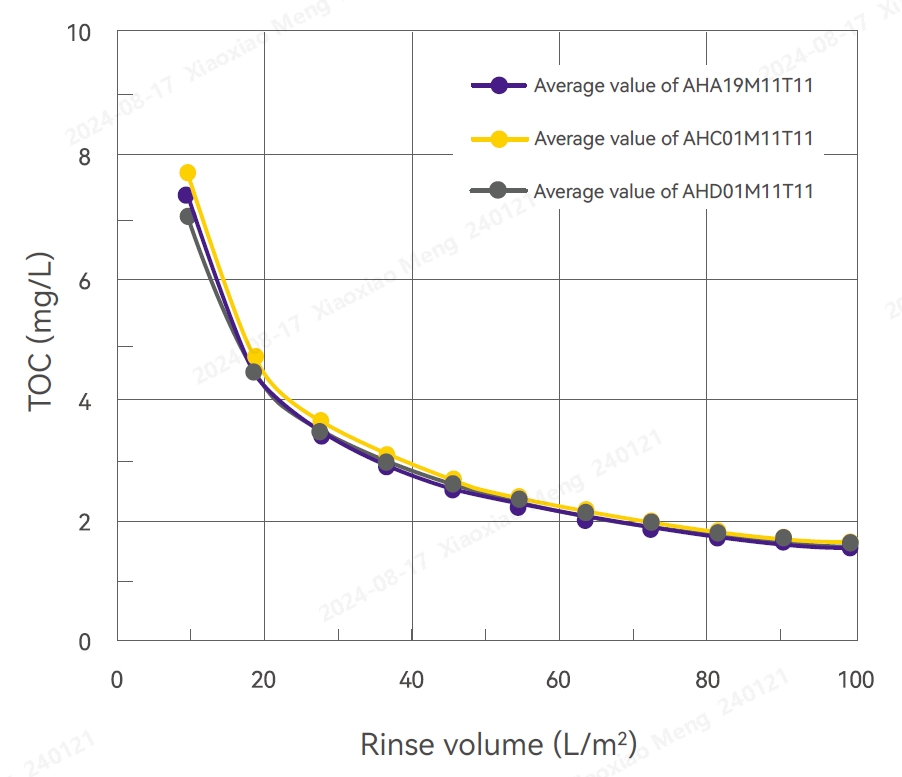

TOC Test Results Test Results of Flow Differential Pressure

Validation Methods and Results

Conductivity

Several filters were randomly selected from different production batches and subjected to high-pressure sterilization at 125°C for 60 minutes. These filters were then rinsed with 100 L/m2 pure water for 10-20 minutes. The conductivity ranged from 2.79 to 7.51 μS/cm

NVR

Several filters were randomly selected from different production batches and subjected to high-pressure sterilization at 125°C for 60 minutes. These filters were then rinsed with 100 L/m2 pure water for 10-20 minutes. The NVR ranged from 667 to 1,314 mg

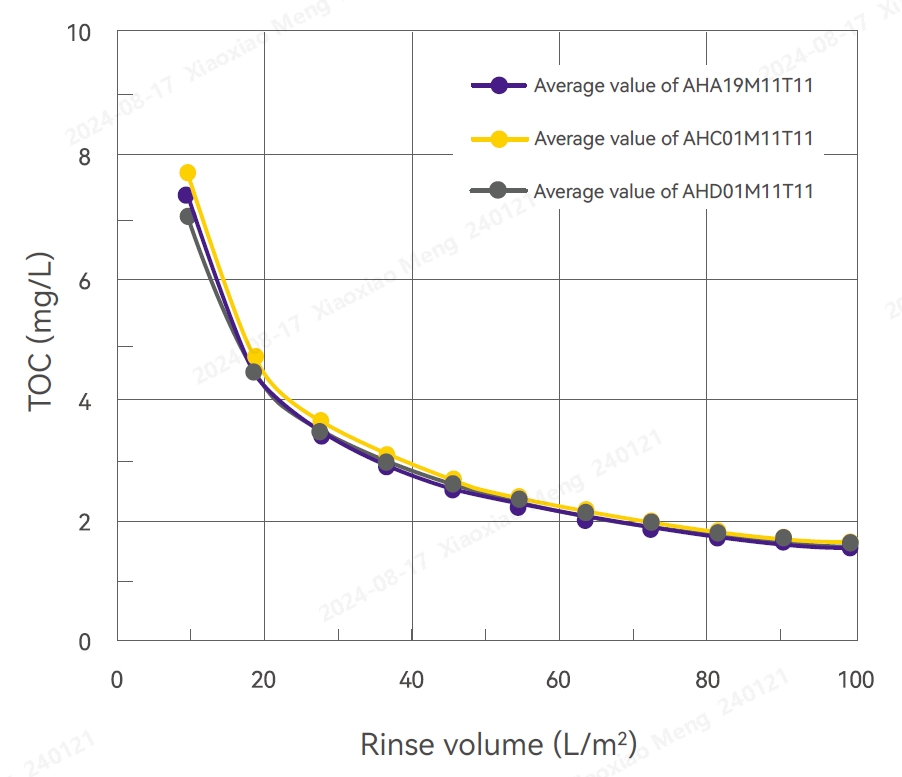

TOC

Several filters were randomly selected from different production batches and subjected to high-pressure sterilization at 125°C for 60 minutes. These filters were then washed with 100 L/m2 pure water for 10-20 minutes. The TOC ranged from 1.12 to 1.55 mg/L

pH

Several filters were randomly selected from different production batches and subjected to high-pressure sterilization at 125°C for 60 minutes. These filters were then rinsed with 100 L/m2 pure water for 10-20 minutes. The pH ranged from 6.10 to 6.62

Endotoxin

Several filters were randomly selected from different production batches, then rinsed with 100L/m2 pure water for 10-20minutes, followed by soaking in pure water for 24 hours. The endotoxin level was <0.25 EU/mL as indicated by Tachypleus Amebocyte Lysate test

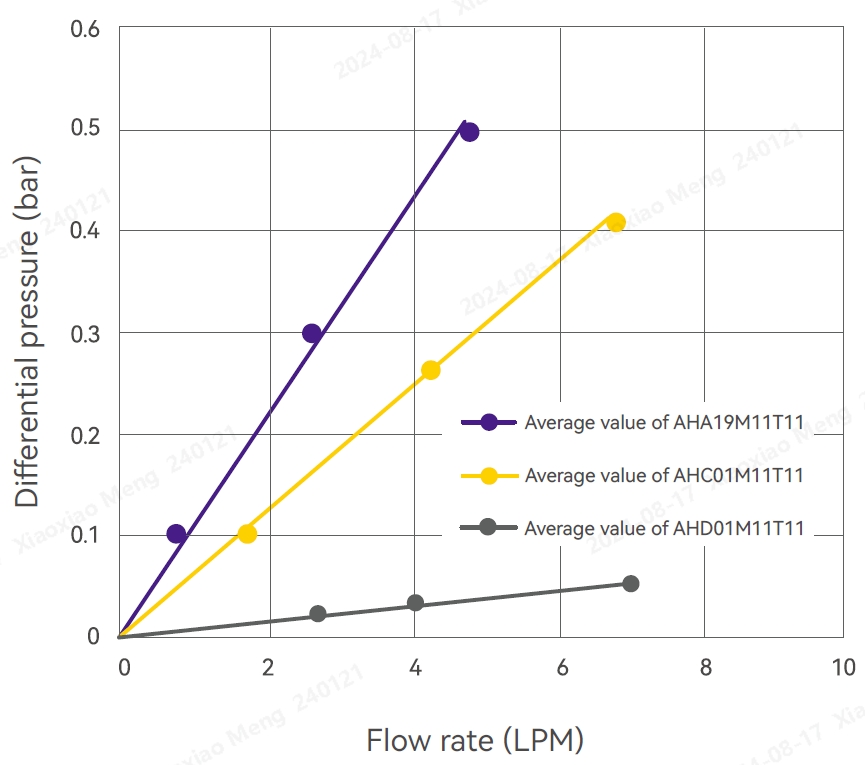

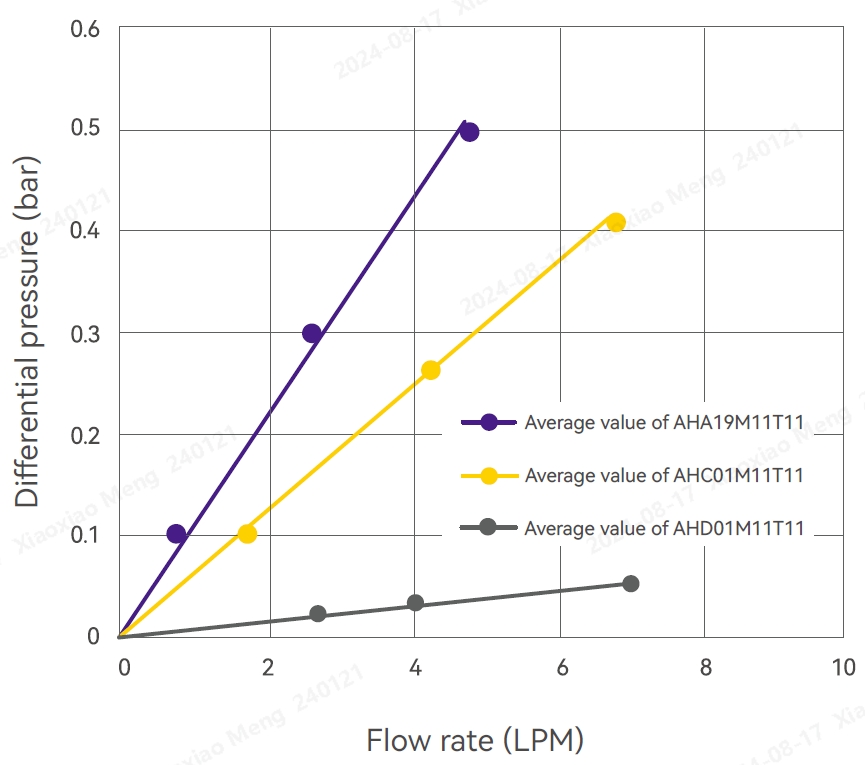

Flow differential pressure

Several filters were randomly selected from different production batches and subjected to high-pressure sterilization at 125°C for 60 minutes. These filters were then rinsed with 100 L/m2 pure water for 10-20 minutes. The experiment was conducted at room temperature. After venting, the flow rate was gradually increased, and the upstream and downstream pressures were observed. Within 8 LPM, the differential pressure was < 0.6 bar

Tolerated liquid pressure

Several filters were randomly selected from different production batches and subjected to high-pressure sterilization at 125°C for 60 minutes, twice. The tightness of filter was tested. High-viscosity solution was filtered to increase the upstream and downstream differential pressure of filter. The filter was subjected to forward and reverse pulse pressures at room temperature, followed by rinsing, drying and tightness challenge test. At room temperature, Alidep® Depth Filter can withstand 3.0 bar forward pressure and 2.0 bar reverse pressure