Depth Stacked Filter

-

-

-

Product Specifications

Product Specifications

Product Series

16 inch 8 cells

16 inch 10 cells

16 inch other

Effective Filtration Area

1.8 m2

2.3 m2

Optional

Height

184 mm

275 mm

-

Materials of

Construction

Filter Media

Filter Media Cellulose, Filter Aid, Resin or Cellulose

Frame and Supporter

Glass Fiber Reinforced Polypropylene

Stainless Steel Band

316L

O-ring

Silicone

Working characteristics

Particle Challenge

Particle Intercept>90%

Max Operation Pressure

3.0 bar @ 25℃

Max Pressure Differentialal

Forward:2.0 bar @ 25℃

Reverse:not recommended

Sterilization

Resistance

In-line steam: 126℃ 30 min, 3 cycles

Indirect Food Additive

All component materials meet the requirements of Indirect Food Additive cited in FDA 21 CFR 177-182

Toxicity

The raw materials of all Alidep® Depth Stacked Filter components meet the biological safety requirements refering to USP<88> Class VI plastic

Bacterial Endotoxin

The endotoxin level of rinsing liquid is <0.25 EU/mL, which complies with the requirements for water for injection in Chinese Pharmacopoeia and United States Pharmacopoeia

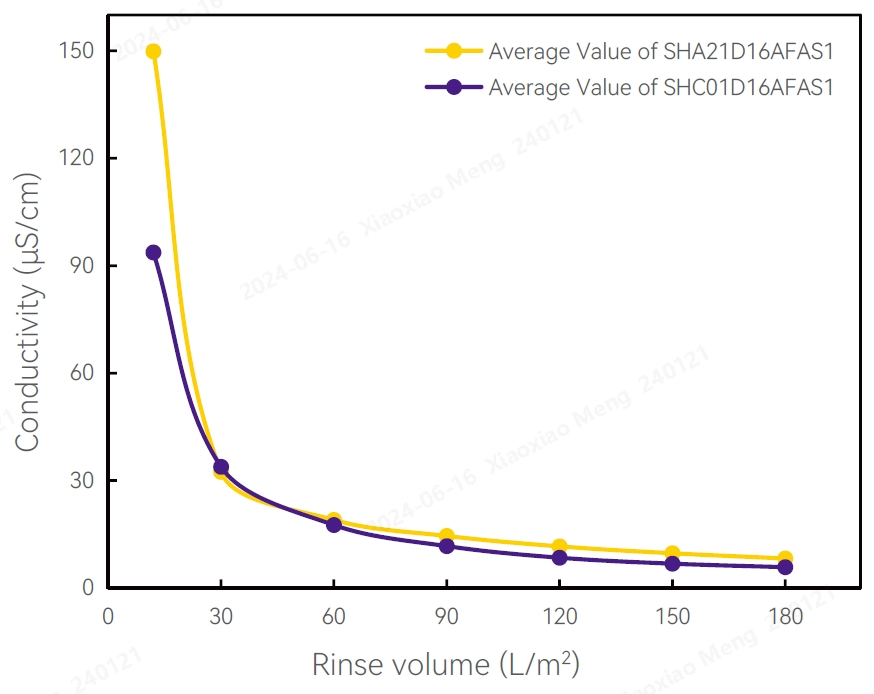

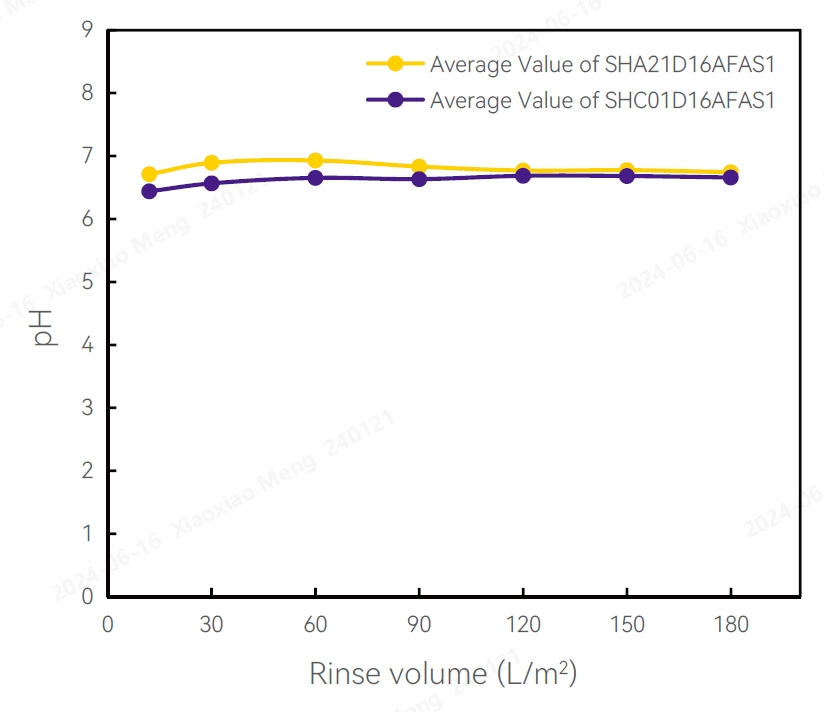

Conductivity Test Results pH Test Results

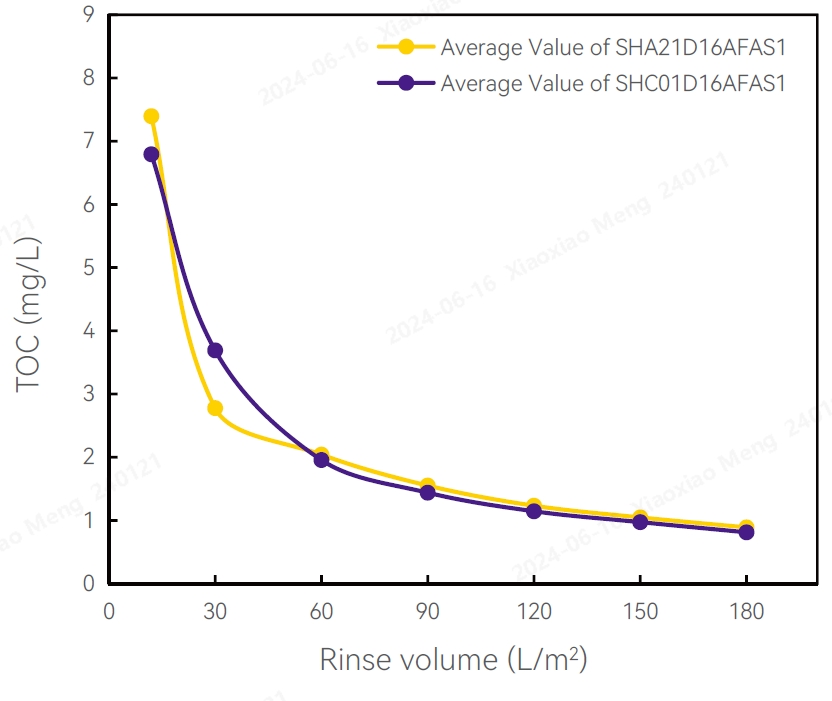

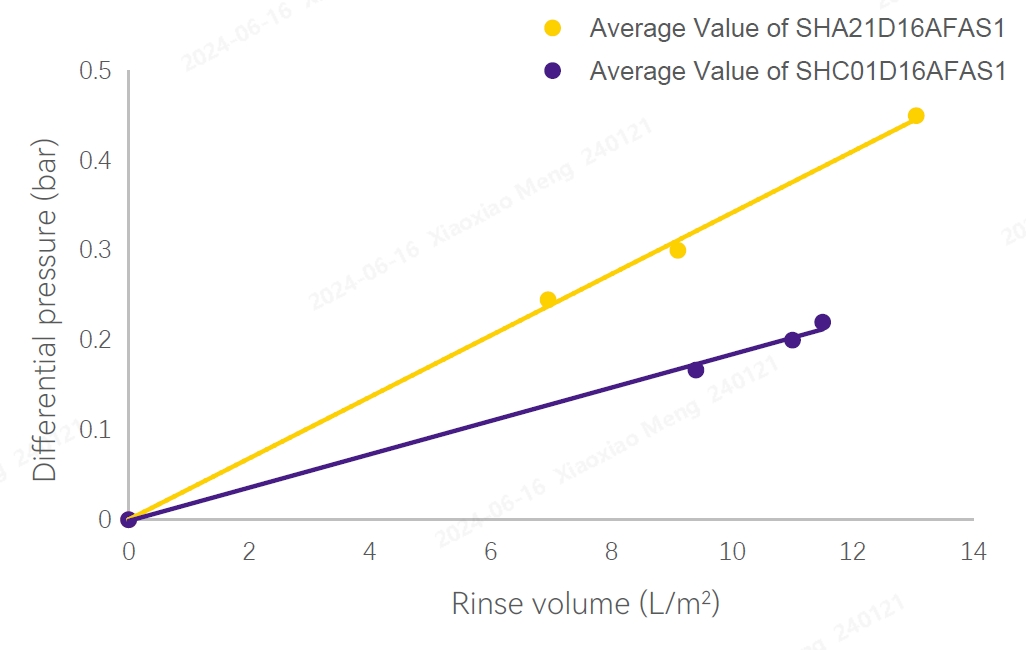

TOC Test Results Test Results of Flow Differential Pressure

Validation Methods and Results

Conductivity

Several filters were randomly selected from different production batches, then rinsed with 100L/m2 pure water for 10-20 minutes. The conductivity ranged from 5-8 μS/cm.

TOC

Several filters were randomly selected from different production batches, then rinsed with 100L/m2 pure water for 10-20 minutes. The TOC was about 1 mg/L.

pH

Several filters were randomly selected from different production batches, then rinsed with 100L/m2 pure water for 10-20 minutes. The pH ranged from 6.6-6.8.

Endotoxin

Several filters were randomly selected from different production batches, then rinsed with 100L/m2 pure water for 10-20 minutes, followed by soaking in pure water for 24 hours. The endotoxin level was < 0.25 EU/mL as indicated by Tachypleus Amebocyte Lysate test.

Endurance to Sterilization

Several filters were randomly selected from different production batches, after 3 cycles of SIP at 126℃ for 30min, filters passed air tightness, diffusion flow, hydraulic stress. Flow rate and pressure dropafter SIP met the product quality standard.

Hydraulic Stress

Several filters were randomly selected from different production batches, respectively conduct hydraulic stress test at ambient temperature and after 3 cycles of SIP at 123℃ for 30 min. High-viscosity solutions was filtered to increase the pressure drop across the filters. Apply forward pulse pressure to the filter at ambient temperature, rinseand conduct diffusion flow. Depth stacked filter can withstand 2.0bar forward pressure at ambient temperature.