Fully Automatic Small-scale Ultrafiltration System

Product Introduction

Alioth Fully Automatic Small-scale Ultrafiltration System, with its modular design and flexible combination options, supports the use of different brands and sizes of filters or hollow fibers, thus achieving various filtration requirements ranging from a minimum of 0.1 m2 to a maximum of 2.5 m2. It features full automatic control, convenient operation, real-time display of operation parameters, and automatic calculation of TMP.

The overall equipment is compact and space-saving, with flexible design and versatile functions. It is suitable for various applications and can meet the regulatory requirements for data integrity in pharmaceutical industry. It is an ideal choice for laboratory-scale process development, pilot-scale drug production, and GMP-level drug manufacturing at different stages and can meet different needs. Customers can configure different functional modules such as flow rate, temperature, pH, conductivity, and UV based on their own process requirements. They can also choose from manual, semi-automatic, and fully automatic control levels to flexibly match the automatic control requirements of different stages. It has a sanitary design and provides complete IQ/OQ verification service and document support. It can be applied in various pharmaceutical production processes, including but not limited to concentration/diafiltration, microfiltration, and unidirectional tangential flow filtration.

Product Properties

- Compatible with different types of consumables, and flat filters or hollow fibers of different areas

- Available in different modules, including volume, temperature, flow rate, pH, conductivity and UV, etc.

- Adaptable for filtration areas around 0.1-2.5 m2

- Can be externally connected to various accessories, such as TCU, to further expand the functional scope and facilitate the use in different processes

- Can dock with external devices to achieve handshake communication and feedback control, etc.

Typical Applications

- Vaccine purification

- Virus purification

- Blood product purification

- Monoclonal antibody purification

PID Flowchart

Product Characteristics

| Membrane area | Common filter series: 0.02-0.3 m2 |

Common filter series: 0.1-0.5 m2 |

Common filter series: 0.5-2.5 m2 |

| Intermediate process tank | 1 L / 2 L | 5 L | 10 L |

| Minimum circulation volume | ~ 100 mL | ~ 200 mL | ~500 mL |

| Power supply | 220 V / 50 Hz | 220 V / 50 Hz | 380 V / 50 Hz |

| Power pump | Available in rotor pump and diaphragm pump | ||

| Operation mode | Available in fully automatic, semi-automatic and manual operations | ||

| System pressure resistance | Maximum 5 bar | ||

| Operating pressure | Maximum 4 bar | ||

| Liquid-contacting material | SS 316 L / EPDM/Silicone | ||

| Operating temperature | 4-40°C recommended for plastic material part; 4-60°C recommended for SS 316 L part (customized SIP design) |

||

| Residual volume | <10 mL | ||

| Pipeline material | SS 316 L | ||

| Sanitary connection method | Sanitary chuck | ||

| Supported languages | Bilingual in Chinese and English | ||

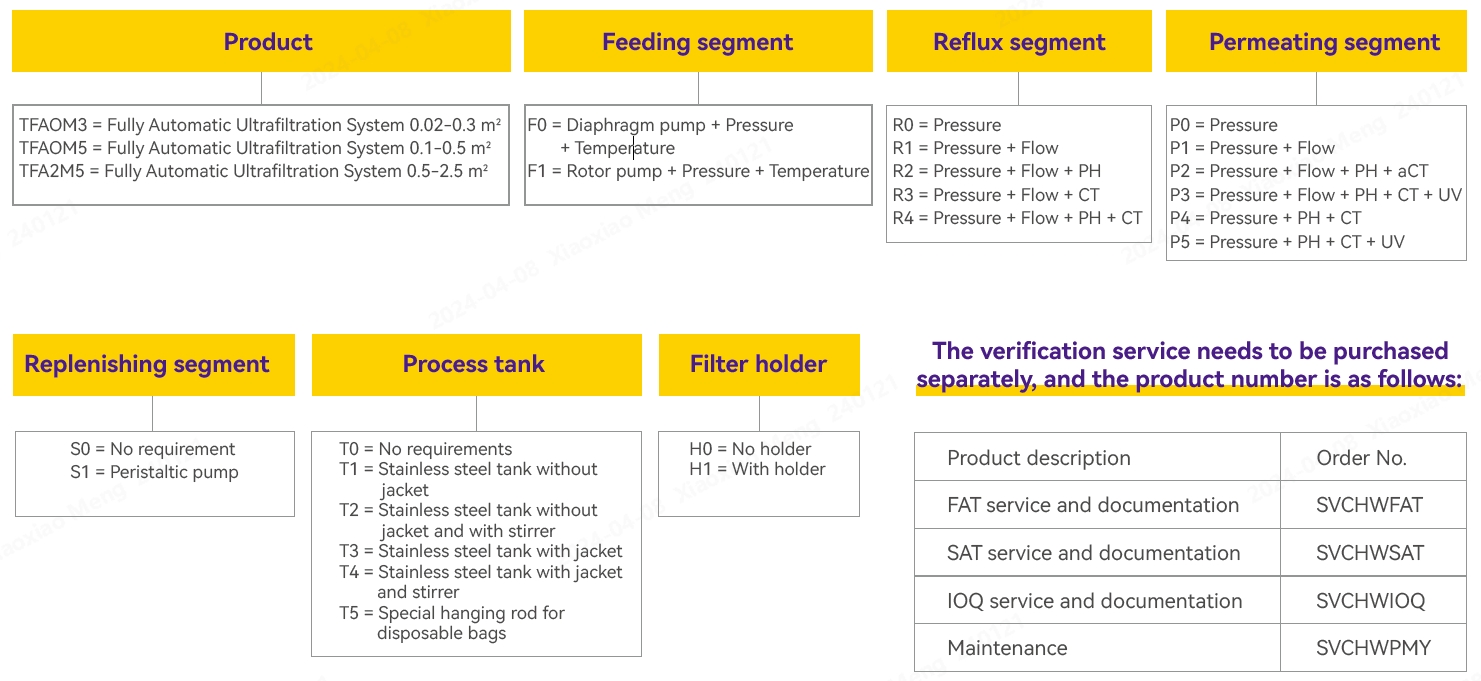

Ordering Information

For further information, please contact us and Alioth technical team will provide a comprehensive service for your filtration process.